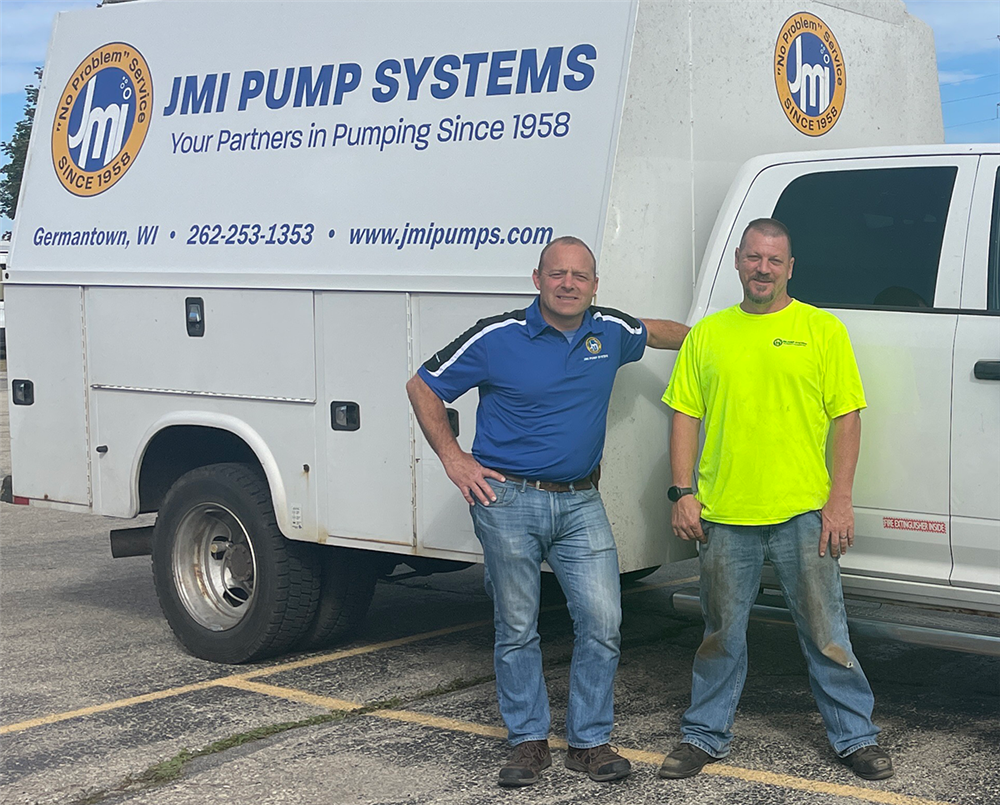

If there’s something unusual about a pump system you’re working with, call JMI Services, LLC.

A wholly owned subsidiary of JMI Pump Systems, JMI Services offers 24/7 support for contractors. Its service team can assist a contractor with an installation or replacement, as well as provide onsite training to individual plumbers or your entire team.

Assisting You with Jobs

“Contact us to troubleshoot any pump job, even if the pump system was not purchased through us,” said Mike Blum, owner of JMI Pump Systems.

The teamwork between JMI Services and contractors can provide businesses with labor savings. Once the basin installation and invert are complete, JMI Services can take the pump system to the final connection, which is done by a licensed plumber.

If there is a pump emergency, and your installers are not available, JMI Services will field calls – even after hours or on weekends – and help troubleshoot or send out the service team if need be.

If a contractor is having difficulty with an installation or replacement, JMI Services has “no problem” troubleshooting or answering inquiries. If questions cannot be answered through the phone, the service team can be dispatched with a fully stocked truck to help the contractor.

The service truck is equipped with sump, effluent, sewage, and grinder pumps; valves; pipe fittings; controls; a pressure washer; a tripod; and more to help with everything from pump and battery backup installations to small lift stations.

Training You for Jobs

“JMI is known for our product knowledge and pump system design,” Mike said. Plus, JMI is willing to help pass its knowledge to its contractors. JMI provides onsite training in pump installation, pump replacement, and specific training on the use of its products.

“Our service team and JMI Services, LLC is one of many ways we are true ‘Partners in Pumping’ with our contractors,” Mike said. “We are different and more than a pump in a box company.”

He emphasized that JMI Services’ customer is the contractor, not the end user of the pump system. For the cost of time and materials, JMI Services will help contractors satisfy their customers. “We bill the contractors, and the contractors bill their customers,” said Mike. “We are not there to compete with our customers; we are simply an extension of them.”

Since 1958, the JMI Pump Systems staff of professionals – over 20 strong with more than 200 years of total experience – has been eager to provide contractors and homeowners like you with solutions to their pump and pump system needs. Serving customers throughout Wisconsin and northeast Illinois, you can count on the pros at JMI Pump Systems to provide the right product at the right time.

For more information on JMI Services LLC, contact Mike Blum at 262-253-1353 or mike@jmipumps.com.

JMI Services LLC, a division of JMI Pump Systems, offers 24/7 support and service to contractors - whether in an emergency, onsite training, or installation help when the contractor’s own installers are not available.

JMI Services LLC, a division of JMI Pump Systems, offers 24/7 support and service to contractors - whether in an emergency, onsite training, or installation help when the contractor’s own installers are not available. In this month’s blog, we are featuring the Franklin Electric Inline 1100 SpecPAK Pressure Boosting System to provide a simplified way to select a packaged system for boosting water pressure in applications requiring more than one pump.

In this month’s blog, we are featuring the Franklin Electric Inline 1100 SpecPAK Pressure Boosting System to provide a simplified way to select a packaged system for boosting water pressure in applications requiring more than one pump.